WHAT WE DO?

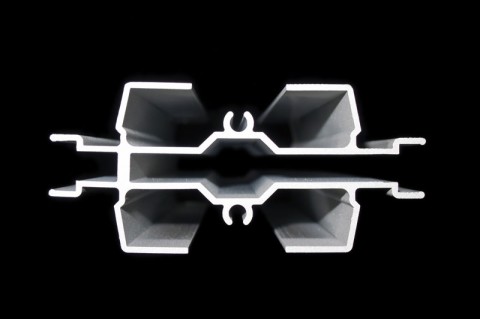

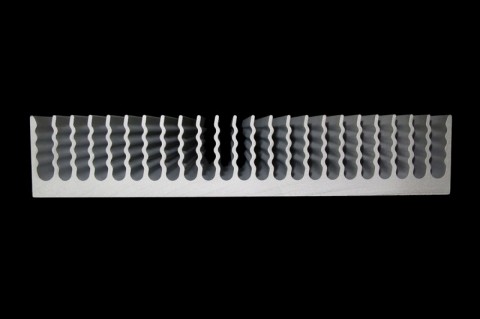

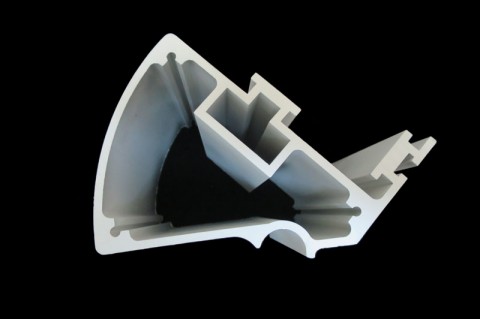

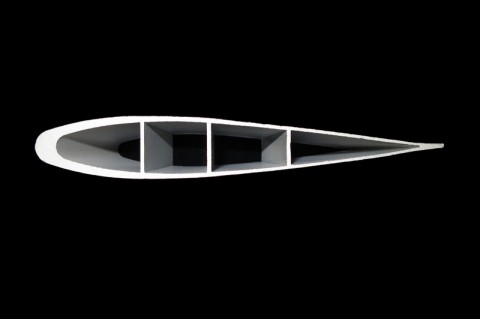

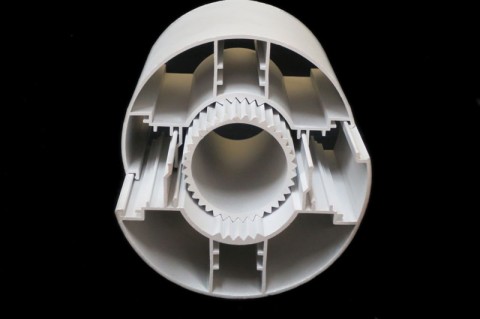

INEXAL S.A. is dedicated to the first transformation of aluminum by extrusion. The aluminum extrusion process involves applying pressure to the aluminum cylinder (billet), passing to a mold (die) to achieve the desired shape. Each type of profile has its matrix and that matrix determines its shape. The billet is heated to facilitate its passage through the matrix, and it is introduced into the press. When extruded profiles exit the press through the matrix, they slide on a bench where they are cooled with air or water, depending on its size and shape, and the characteristics of the alloy involved and properties required. Then, they are stretched to obtain aluminum profiles straight and eliminate any tension in the material. Afterwards, they are cut into suitable lengths and artificially aged to achieve adequate strength.

In addition to standard extruded profiles, INEXAL S.A. specializes in profiles designed to shape their ideas. Their profiles are aimed at engineering, architecture and interior design.

-

Capacity

- 2200 TON Press

- Production capacity exceeding 8000TON profile per year

- Maximum length of profile cutting 7m

- Top alloys 6060, 6063, 6005, 6086